How to Handle Body Filler Bleed-Through During Automotive Refinish: A Practical B2B Guide for Distributors and Repair Shops

When a vehicle returns from repainting and the area patched with body filler (commonly called “polyester putty” ) looks noticeably lighter than the surrounding finish, you’re likely seeing body filler bleed-through — a frustrating and sometimes costly problem. This issue is especially common with light metallic basecoats (light blue, light green, pale silver) where the affected area shows as paler or slightly discolored. For import agents, wholesalers, paint shop owners and fleet managers, understanding the cause, prevention and repair workflow is essential to protect your reputation, reduce rework costs and improve margins.

What is body filler bleed-through?

Body filler bleed-through occurs when materials in the cured body filler or its hardener interact with the topcoat pigment or binders, causing local discoloration or bleaching of the finish. It usually appears after the topcoat is sprayed and cured, and shows up as a lighter, washed-out patch over the repaired area.

Main causes

1. Excess hardener in the body filler. Some hardeners contain oxidizing components or additives that can chemically attack pigments in the basecoat or clearcoat, causing a bleaching/oxidation effect when they migrate to the surface. Over-use or incorrect ratios increase this risk.

2. Low-quality body filler. Inferior formulations may not fully cure, may release reactive substances during or after cure, or may contain fillers/chemistries that stain or affect topcoat pigments.

Prevention: processes and product choices you should insist on

Preventing bleed-through is far cheaper and faster than repairing it later. For B2B customers (distributors, shop owners and fleets), these are the best practices to standardize and promote:

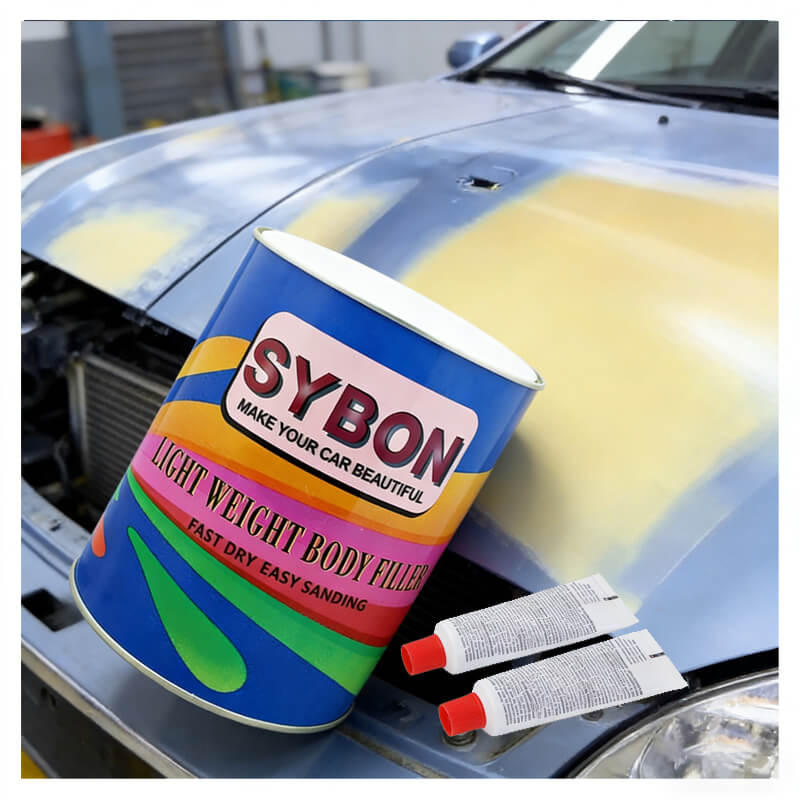

- Use high-quality body filler from reputable suppliers. Choose body filler formulated for automotive refinishing that states compatibility with modern topcoats. Require technical data sheets and cure-time data from suppliers.

- Follow correct mix ratios. Always mix body filler and hardener at the manufacturer’s recommended ratio. Train technicians and provide clear measuring tools or cartridges to avoid guesswork.

- Perform compatibility tests. Before large jobs, test the body filler + hardener + primer + topcoat stack on scrap metal or plastic to ensure no adverse interaction. This is a simple QA step that avoids customer complaints.

- Thorough surface preparation. Remove oil, wax, dirt and contaminants before applying body filler. Contaminants can both interfere with body filler adhesion and cause local chemical reactions.

- Seal with an appropriate primer/sealer. After shaping and sanding the body filler, apply a compatible primer or sealer that isolates the body filler from the topcoat. A good sealer prevents migration of reactive substances.

- Control hardener selection and temperature. Hardener speed and ambient temperature affect cure chemistry. Use the recommended hardener grade for the body filler and shop conditions.

If bleed-through has already occurred — a practical repair workflow

When you discover discoloration after topcoating, assess severity first. Below is a pragmatic step-by-step approach that repair shops and body shop supervisors can follow:

1. Evaluate the patch. Is the effect superficial (only the topcoat discolored) or has it penetrated deeper to the primer/body filler? Light surface bleaching is simpler to fix.

2. Spot-sand and respray (mild cases). If only the topcoat is affected:

- Sand the affected area lightly to remove the discolored topcoat (feather to surrounding paint).

- Clean with solvent, then reapply primer/sealer if sanding reached the primer.

- Refinish with basecoat and clearcoat, following standard spray and flash times.

3. Remove body filler and redo repair (severe cases). If sanding back reveals that the body filler or primer is still causing staining:

- Grind/sand out the body filler layer fully to sound substrate.

- Re-prepare the area (clean, degrease, apply etch primer if needed).

- Reapply high-quality body filler in correct ratio, sand, seal with an appropriate primer/sealer, then refinish.

4. Document and test. Record the corrective steps and, if possible, test a small area on scrap to confirm no reoccurrence before returning the car.

Operational recommendations for distributors and shops

- Stock quality body filler and technical datasheets. When offering body filler to customers, include clear instructions on hardener ratios and surface prep.

- Offer training and demo samples. Sell value: provide short training sessions or demo kits so shops can see how to mix and seal correctly.

- Guarantee support and sample testing. Be ready to receive small panels from customers for compatibility testing — this builds trust and reduces disputes.

Why SYNEW is the right partner for your refinish needs

SYNEW combines reliable product quality with competitive pricing and a one-stop procurement model. While our global brand recognition may not match some large multinationals, our formulations and quality control are engineered to meet the same performance expectations — at a better value. For distributors and repair shops looking to reduce rework and preserve profit margins, SYNEW’s automotive refinish lineup (including premium body fillers, hardeners, primers and clearcoats) is tailored to deliver consistent results when used as instructed.

SYNEW is actively seeking global agents and distributors. If you’re an importer, dealer, body shop owner or fleet manager and would like to test our products, we welcome sample requests. Send your inquiry through our website — provide your contact and shipping information — and we will respond within 24 hours. Partner with SYNEW to lower costs, improve finish quality and win more local business.

Source of this article:https://www.synewchemical.com/

Get to know us through more channels:Youtube.