What is the best way to sand paint off a car? — A practical guide for professionals and repair shops

If you’ve asked “What is the best way to sand paint off a car?”, the short answer is: it depends — on the size of the job, the condition of the underlying metal or filler, the type of paint being removed, and your goals (partial blend, full strip, or prep for primer). Below is a clear, professional guide that explains the common methods, gives safe, practical steps, and helps you decide what method will deliver the best results for your workshop or fleet.

Safety first

Before any paint removal begins, protect yourself and the environment. Wear an appropriate respirator (NIOSH-rated for organic vapors and particulate matter), safety goggles, gloves, and coveralls. Older vehicles may have lead-based paint — if there’s any chance of this, treat the job as hazardous and follow local regulations for containment and disposal. Work in a well-ventilated area and capture dust with vacuums fitted with HEPA filters wherever possible.

Methods overview — pros and cons

1. Hand sanding (manual sanding blocks)

- Best for small repairs, feathering edges, and delicate contours.

- Use a sanding block to keep pressure even. Start with a coarse grit only if you must remove thick layers; otherwise use finer grits to feather and prep.

- Pros: low cost, precise control. Cons: slow for large areas, labor-intensive.

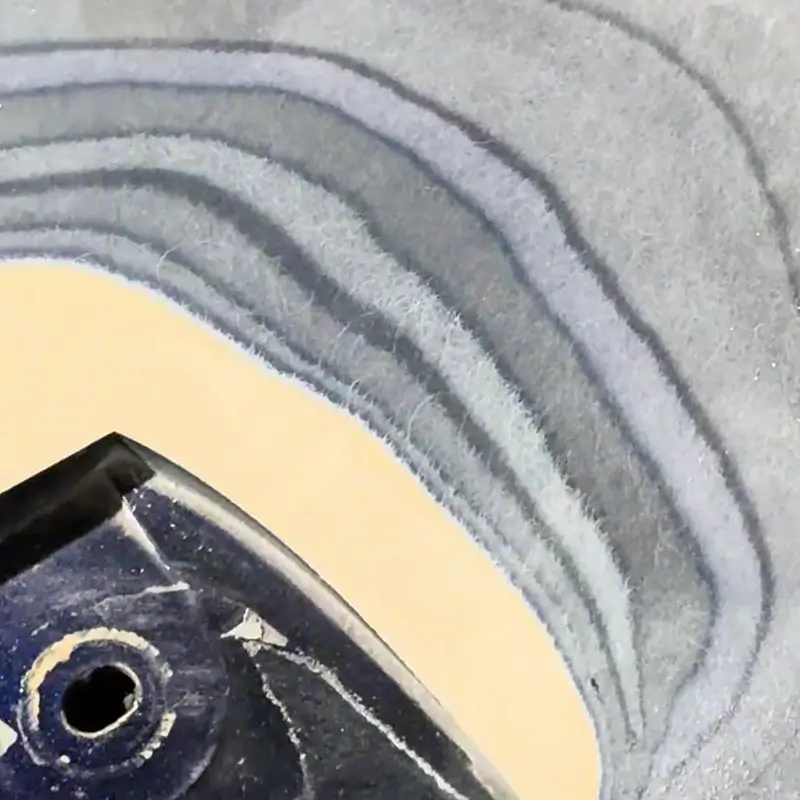

2. Dual-action (orbital) sanders

- The most practical “best” tool for many body shops when removing paint from panels without heavy stripping. Use an orbital sander with appropriate backing pads and sandpaper discs.

- Start with a relatively coarse disc (e.g., 80–120 grit) to remove top coats, then progress through 180–320 grit to smooth the surface. Finish with 400–600 grit when prepping for primer or sealer.

- Pros: fast, reduces gouging if used properly. Cons: can create low spots if held in one place or used with too coarse a grit.

3. Mechanical grinding (with care)

For heavily bonded coatings or rust, you might need a grinder with flap discs or sanding discs — but this requires experience to avoid damaging thin metal. Only used by experienced technicians.

4. Chemical strippers

Useful for removing paint from complex shapes, seams, or areas where mechanical sanding would be impractical. Requires strict PPE and careful disposal. Often used in combination with mechanical methods.

5. Media blasting (sand, soda, or glass bead)

- Fast and effective for full-strip jobs down to bare metal. Choose the media carefully: soda is gentler and can be suitable for aluminum or thin metal; glass bead or garnet is more aggressive.

- Pros: efficient for full restoration. Cons: requires specialized equipment, containment, and post-blast cleaning; can distort thin panels if overdone.

6. Heat guns

For paint peeling in small areas or removing decals/adhesives. Use cautiously to avoid burning the substrate or releasing harmful fumes.

Best practices & step-by-step approach

1. Assess the job — Is this a spot repair, panel respray, or full strip? Choose your method accordingly.

2. Remove trim and mask surrounding areas — Plastics, chrome, and seals can be damaged by sanding or chemicals.

3. Start with the least aggressive method — For most panel work, begin with orbital sanding rather than immediately calling in a blast or heavy grinder.

4. Progress grits logically — Coarse to remove paint, then finer to feather and smooth. This avoids unnecessary metal removal.

5. Keep the sander moving — Never hover in one spot; maintain even pressure and sweep motions to avoid low spots.

6. Check frequently — Stop and feel the panel often; visual inspection plus hands-on checking prevents mistakes.

7. Clean thoroughly — After sanding or stripping, remove dust, oils, and contaminants with an appropriate cleaner before priming.

8. Protect bare metal — If you expose bare metal, apply an etch primer or corrosion inhibitor promptly.

Why method choice matters

Choosing the right method preserves panel integrity, reduces rework, and improves adhesion of primers and topcoats. For many body shops and repair centers the balance of speed, control, and finish quality makes the orbital sander (used with a graded sanding progression and correct technique) the best practical answer to “What is the best way to sand paint off a car?”

SYNEW — high-performance refinish products that give you an edge

SYNEW is one of China’s leading automotive paint manufacturers, supplying high-performance automotive refinish products to dealers, distributors, fleet owners, and repair shops worldwide. If you’re asking “What is the best way to sand paint off a car?” because you want a professional finish ready for repainting, SYNEW’s range of primers, fillers, basecoats and clearcoats are formulated to work seamlessly with standard surface-prep techniques — delivering results comparable to major global brands but at a far more attractive price point.

We may not have the same global name recognition as some established multinational brands, but our product quality is nearly identical — and our prices are purposefully competitive. That makes SYNEW an ideal partner if you want to keep customer satisfaction high while protecting margins and expanding local market share.

Who should work with SYNEW?

If you are a distributor, paint shop owner, repair center manager, or fleet maintenance professional looking for affordable, high-quality refinish products, SYNEW can support your business growth. Our product line covers everything from sand-through primers and lightweight body fillers to high-gloss clearcoats and mixing accessories — a one-stop solution for automotive refinish needs.

Trial, partnership, and contact

We welcome distributors and repair shops to request samples for testing. If you’re interested in becoming a SYNEW distributor or want product samples for evaluation, please contact us through our website and send an inquiry via the contact email form. We promise to respond within 24 hours and are eager to explore mutually beneficial partnerships that help you raise service quality and profitability.

If your next step is repairing a panel or specifying refinish materials, pair the correct sanding method with SYNEW’s refinish products for a professional result that’s cost-effective and reliable. If you’d like sample materials or technical datasheets, contact SYNEW through our website today — let’s grow your business together.

Source of this article:https://www.synewchemical.com/

Get to know us through more channels:Youtube.