How to Evaluate Auto Refinish Paint Quality: 5 Key Indicators Every Distributor and Repair Shop Should Know

In the competitive world of aftermarket refinishing, auto refinish paint quality directly determines finish appearance, longevity, and customer satisfaction. Whether you are an import agent, distributor, fleet owner, or bodyshop operator, knowing how to evaluate paint performance is essential for choosing products that reduce rework, protect reputation, and maximize profits. Below are five practical, industry-focused indicators that will help you assess the real-world quality of any refinish paint system.

1. Color consistency (color match and stability)

The first and most visible test of auto refinish paint quality is how closely a repair matches the original vehicle color and how stable that color remains over time. Good products offer high color accuracy out of the can and predictable behavior after spraying and curing. Evaluate color consistency by:

1. Spraying standardized test panels and comparing under controlled light (standard daylight and a color-corrected light booth).

2. Using spectrophotometer readings for metal flake and pearl finishes.

3. Reviewing tolerance for metamerism (how the color appears under different light sources).

Metallic and pearl finishes are especially demanding; choose paint systems that provide clear mixing guidelines and reproducible flake/pearlescent effects.

2. Adhesion (bond to substrate and primer)

Adhesion performance tells you whether the paint will remain bonded under thermal cycling, vibration, and routine mechanical stress. Poor adhesion equals delamination, flaking, and costly callbacks. To evaluate:

1. Use cross-cut adhesion tests and pull-off tests on representative substrates (steel, aluminum, OEM coatings, and common plastic bumpers).

2. Inspect panels after environmental stress (hot/cold cycles, humidity exposure) to detect early failure modes.

High-quality auto refinish paints will adhere well to properly prepared surfaces and compatible primers, showing minimal loss in adhesion after accelerated testing.

3. Weather resistance (UV, chemical and thermal stability)

Durability in real-world climates is a core part of auto refinish paint quality. Paints must resist UV fade, acid rain, bird droppings, and temperature swings. Key evaluation steps:

1. Run accelerated weathering tests (QUV or xenon arc) to simulate long-term sun and moisture exposure.

2. Test chemical resistance with common contaminants (fuel, detergents, solvents).

3. Examine gloss retention and colorfastness after exposure.

Reliable systems show minimal chalking, cracking, or yellowing and retain gloss and color over extended cycles.

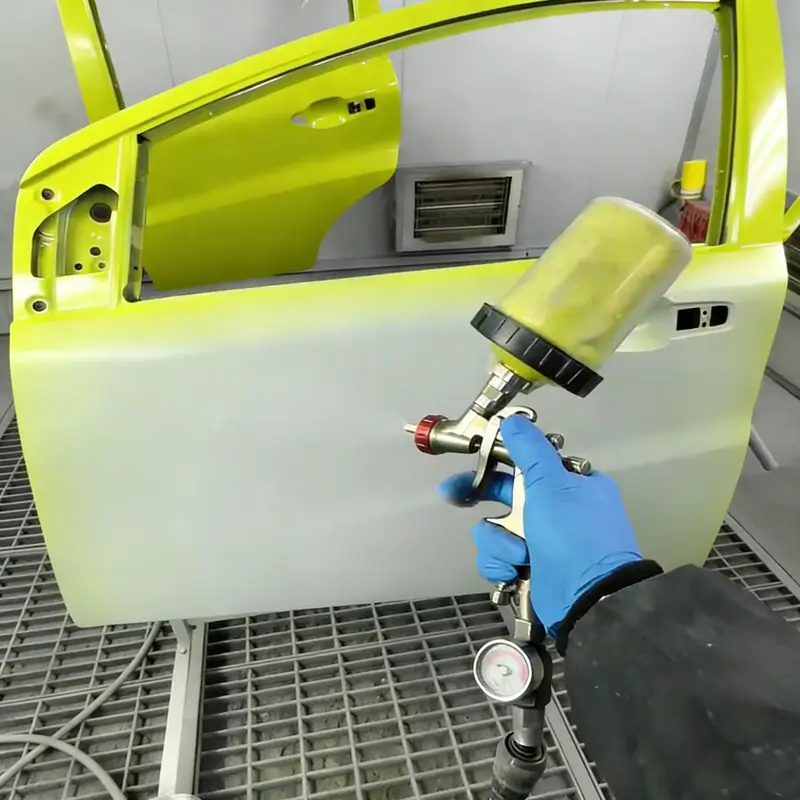

4. Application performance (sprayability, coverage, cure)

A paint’s field performance affects labor time and finish consistency—critical for distributors selling to high-volume shops. Important practical checks include:

1. Sprayability and atomization: Does the paint produce uniform fogging with standard HVLP or gravity-feed guns?

2. Opacity/coverage: How many coats are required to hide the substrate or primer? Better coverage reduces material cost and shop time.

3. Drying and cure profile: Faster but controllable dry times reduce bottlenecks; however, overly fast skins can cause poor flow.

4. Sandability and intercoat adhesion: Is sanding between coats clean and predictable?

Test paints under the actual equipment and booth conditions used by your customers to see real-world performance.

5. Final film appearance (gloss, smoothness and defects)

The finished surface is the final proof of auto refinish paint quality. Evaluate the cured film for:

1. Gloss level and uniformity (measured with a gloss meter and verified by eye).

2. Surface texture: absence of orange peel, dust nibs, or fisheyes.

3. Transparency and depth—especially important for basecoat/clearcoat systems where depth and clarity define perceived value.

Professional-grade paints should deliver a mirror-like finish with consistent gloss and low surface defects when applied correctly.

Why choose SYNEW?

SYNEW’s product range balances proven auto refinish paint quality with competitive pricing and one-stop sourcing for automotive refinish needs. While our brand may be less recognizable than some global names, our formula stability, color reproduction, and durability closely match major-brand performance—at a cost profile tailored for distributors and repair shops that need margin and reliability. SYNEW is one of China’s leading refinish manufacturers sought by agents and distributors for its value-for-money offering.

If you’re an importer, distributor, bodyshop owner, or fleet manager and you want to test SYNEW products, we welcome sample requests and distribution inquiries. Request samples for lab testing or shop trials—if you’re interested in becoming a SYNEW distributor or purchasing for your business, please contact us through the email form on our website. We promise to reply within 24 hours and support you with product data, training, and marketing support to help you open local market opportunities and boost profits.

Source of this article:https://www.synewchemical.com/

Get to know us through more channels:Youtube.