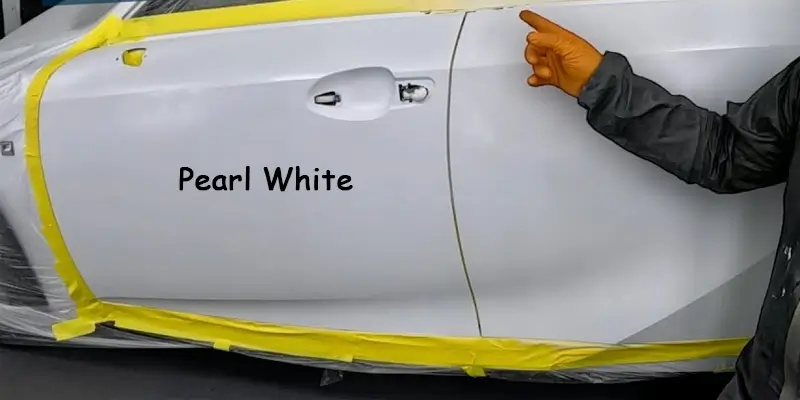

Why is a pearl white car more expensive? — Answer for distributors and what SYNEW offers

For many distributors who are new to automotive refinish, one often-asked question is: Why is a pearl white car more expensive? At surface level it seems “just a color,” but in the automotive paint world pearl white is a technically demanding finish that requires special materials, skilled application, and tighter quality control. Below I’ll explain the main reasons behind the higher cost, what distributors should consider when offering pearl white products to their customers, and how SYNEW’s pearl white solutions are designed to meet those needs while giving distributors a strong competitive product.

The real reasons pearl white cars cost more

1. Complex multi-layer systems

Pearl white finishes are rarely a single coat. Typical refinish systems include a primer, a carefully matched basecoat, one or more pearl/pearlescent effect layers, and a high-quality clear coat. Each layer must be compatible and applied in correct sequence and thickness to achieve the desired depth and shift. More layers = more paint, more labor, and more time.

2. Costly pearlescent pigments

The “pearl” effect comes from special pigments — mica flakes coated with metal oxides or other proprietary materials — that reflect and refract light. These pigments are more expensive than standard pigments. They also may require specially formulated binders to keep the effect stable, which increases material cost.

3. Higher material consumption & waste

Because pearl pigments often don’t hide underlying substrates as well as opaque solids, installers frequently need additional coats or precise application techniques to get even coverage and consistent effect. That raises material usage and can increase scrap and rework when panels are not matched correctly.

4. Color matching and inventory complexity

Pearl whites shift with viewing angle and light conditions, so matching across different panels (or matching a repaired area to factory finish) is harder. Distributors must either carry more SKUs or provide reliable tinting/matching systems and technical support to customers. That logistic and inventory complexity has cost implications.

5. Greater skill and process control required

Application technique, spray pressure, gun setup, ambient conditions, and curing all affect the final effect. Shops may need more experienced painters and stricter process controls — increasing labor cost and lowering throughput compared with non-effect colors.

6. Quality control and testing

To guarantee a consistent pearl effect, additional QC steps (visual checks, sample panels, controlled curing, adhesion and appearance testing) are common. Those processes add time and overhead for manufacturers and refinish shops alike.

7. Perception and resale value

Finally, pearl and metallic finishes are perceived as higher-end by many buyers. Manufacturers price those options higher, and that flows into the aftermarket and repair markets — pearl finishes command a premium because customers expect a premium look and durability.

What distributors should care about

When you plan to offer pearl white coatings to customers (bodyshops, fleet owners, dealers), you’ll want to evaluate suppliers against practical distributor concerns:

- Consistency: Will the color formula produce repeatable results across batches?

- Support: Is technical application support available (mixing ratios, gun settings, troubleshooting)?

- Samples/MOQs: Can you request samples and small trial quantities without high minimum orders?

- Price / margin: Is the product priced to allow competitive quotes while maintaining distributor margin?

- Packaging & logistics: Are packaging sizes suitable for your market, with clear lead times?

- Training & marketing materials: Can the manufacturer provide color chips, repair guides, and training to help your customers succeed?

How SYNEW answers “Why is a pearl white car more expensive?” for distributors

SYNEW understands exactly why distributors worry about pearl finishes — and we build solutions around those concerns.

- Premium pearl formulations: Our pearl whites are formulated with high-quality pearlescent pigments and stable binders so the effect is vivid, consistent, and durable. That reduces on-site rework and keeps end-customer satisfaction high.

- Direct manufacturer supply — no middleman: SYNEW manufactures and supplies paint directly to distributors and agents. By removing intermediaries we offer competitive pricing while maintaining product integrity and traceability. Distributors get factory-direct value and better margins.

- One-stop procurement: SYNEW provides full refinish systems (primers, basecoats, pearlescent effects, high-performance clear coats, and compatible additives). Your customers can buy complete, matched systems rather than mixing components from different vendors — this cuts down color mismatch risks and simplifies ordering.

- Technical support & training: We provide application guidelines, spray parameter recommendations, and troubleshooting support to help bodyshops achieve the correct pearl effect quickly. For larger partners, we offer training and demo panels so their painters learn the right technique.

- Samples and flexible MOQ: SYNEW welcomes sample requests and test panels. We understand distributors need to demonstrate performance before committing — request samples to evaluate match, coverage, and final appearance.

- Quality with cost-efficiency: SYNEW balances high-quality raw materials and in-house production efficiency to deliver a product whose performance is comparable to big-name brands — but at a better price point for distributors who want to win local market share.

- Professional, efficient, integrity: These are our core values — we strive to respond fast, support professionally, and operate transparently so distributors can build trust with their clients.

Why choose SYNEW as your pearl white supplier

SYNEW is one of China’s leading automotive paint manufacturers, producing and distributing a full range of automotive refinish products. Our customers — from agents and distributors to fleet owners and repair shops — repeatedly give positive feedback on coverage, color stability, and value. While our brand may not yet be as globally recognized as the largest incumbents, our product quality is extremely competitive and offers clear cost-performance advantages. If you want a pearl white product that looks premium but keeps your margins healthy, SYNEW is built to be that partner.

Call to action

If you’re a distributor, agent, paint shop owner, fleet manager, or repair center owner and you’re interested in testing SYNEW’s pearl white auto paint, we strongly encourage you to request samples. Please contact us via our website and send an email — once we receive your inquiry we will respond within 24 hours. Let’s work together to bring high-quality, cost-effective pearl white finishes to your market and help you win more business.

Source of this article:https://www.synewchemical.com/

Get to know us through more channels:Youtube.